Metric Full Threaded Studs Bolts BS 4882

| Diameter of plain portion,maximum and minimum sizes of studbolts : metric series | ||||

|---|---|---|---|---|

| Nominal diameter | Nominal diameter design | Reduced diameter design | ||

| max. | min.1) | max. | min.1) | |

| M10 x 1.5 | 10.0 | 9.78 | 7.49 | 7.27 |

| M12×1.75 | 12.0 | 11.73 | 9.07 | 8.85 |

| (M14×2) | 14.0 | 13.73 | 10.64 | 10.37 |

| M16×2 | 16.0 | 15.73 | 12.54 | 12.27 |

| M20×2.5 | 20.0 | 19.67 | 15.71 | 15.44 |

| (M22×2.5) | 22.0 | 21.67 | 17.61 | 17.34 |

| M24×3 | 24.0 | 23.67 | 18.86 | 18.53 |

| M27×3 | 27.0 | 26.67 | 21.71 | 21.38 |

| M30×3 | 30.0 | 29.67 | 24.56 | 24.23 |

| M33×3 | 33.0 | 32.61 | 27.41 | 27.08 |

| M36×3 | 36.0 | 35.61 | 30.26 | 29.87 |

| M39×3 | 39.0 | 38.61 | 33.11 | 32.72 |

| M42×3 | 42.0 | 41.61 | 35.96 | 35.57 |

| M45×4 | 45.0 | 44.61 | 37.54 | 37.15 |

| M48×4 | 48.0 | 47.61 | 40.38 | 39.99 |

| M52×4 | 52.0 | 51.54 | 44.18 | 43.79 |

| M56×4 | 56.0 | 55.54 | 47.98 | 47.59 |

| M64×4 | 64.0 | 63.54 | 55.58 | 55.12 |

| M70×4 | 70.0 | 69.54 | 61.38 | 60.92 |

| M72×4 | 72.0 | 71.54 | 63.18 | 62.72 |

| M76×4 | 76.0 | 75.54 | 67.08 | 66.62 |

| M82×4 | 82.0 | 81.46 | 72.28 | 72.24 |

| M90×4 | 90.0 | 89.46 | 80.38 | 79.84 |

| M95×4 | 95.0 | 94.46 | 85.11 | 84.57 |

| M100×4 | 100.0 | 99.46 | 89.86 | 89.32 |

| 1)Based on tolerance class h13 of BS 4500. | ||||

Studbolts

General

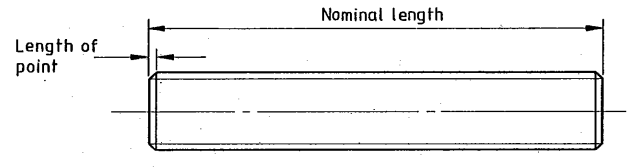

The forms of the studbolts shall comply with those shown in figure

1.Dimensions

shall be as given in 2.1.2 to 2.1.8 and tables 5 to 8.

| Tolerances on nominal length of studbolts : metric series | |||

|---|---|---|---|

| Nominal diameter | Length | Tolerances on length | |

| mm | mm | ||

| ≤M24 | ≤ 150 | ± 0.75 | |

| >150 | ± 1.00 | ||

| > M24 ≤ M48 | ≤ 180 | ± 1.00 | |

| >180 | ± 1.5 | ||

| >M48 ≤ M100 | All | ± 2.00 | |

| (Sizes M14 and M22 are non-preferred.) | |||

| *(Studbolts only.) | |||

| Preferred nominal lengths of studbolts: metric series (based on flange designs as specified in BS 4504) | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal diameter | ||||||||||||||||||||||||||||||||||

| Preferred nominal lengths | ||||||||||||||||||||||||||||||||||

| 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 220 | 240 | 260 | 280 | 300 | 340 | 360 | 380 | |

| M10 | ||||||||||||||||||||||||||||||||||

| M12 | x | x | x | x | x | x | x | |||||||||||||||||||||||||||

| (M14)1) | ||||||||||||||||||||||||||||||||||

| M16 | x | x | x | x | x | |||||||||||||||||||||||||||||

| M20 | x | x | x | x | x | x | ||||||||||||||||||||||||||||

| (M22)1) | ||||||||||||||||||||||||||||||||||

| M24 | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||

| M27 | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| M30 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||

| M33 | x | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||

| M36 | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| M39 | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| M421) | ||||||||||||||||||||||||||||||||||

| M45 | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| M48 | x | |||||||||||||||||||||||||||||||||

| M52 | x | x | x | x | x | x | ||||||||||||||||||||||||||||

| M56 | x | x | x | x | x | |||||||||||||||||||||||||||||

| M64 | x | x | x | x | ||||||||||||||||||||||||||||||

| M70 1) | ||||||||||||||||||||||||||||||||||

| M72 | x | |||||||||||||||||||||||||||||||||

| M76 1) | ||||||||||||||||||||||||||||||||||

| M82 1) | ||||||||||||||||||||||||||||||||||

| M90 1) | ||||||||||||||||||||||||||||||||||

| M95 1) | ||||||||||||||||||||||||||||||||||

| M100 1) | ||||||||||||||||||||||||||||||||||

| 1)Preferred nominal lengths to be completed in a later revision of this standard. | ||||||||||||||||||||||||||||||||||

| NOTE. Choice of length. (a) Minimum length. The minimum length of studs or studbolts has to ensure a full engagement of nut, Le with the point protruding above the face of the nut. (b) Maximum length. There is no precise limit on the maximum length of thread although under normal circumstances, unnecessarily long studs and studbolts are avoided due to cost, and preventing corrosion or unintentional damage to the exposed thread making subsequent nut removal more difficult. Studs and studbolts may be chosen as the next nominal length greater than that required for the thicknesses and tolerances on the bolted components (e.g. flanges, gaskets, washers). The availability of 'stocked" lengths may also be taken into account Unnecessary shortening of studs and studbolts should be avoided. Where studs and studbolts are shortened the original manufacturer's identification and grade marking should be retained. |

||||||||||||||||||||||||||||||||||

| Length of point for studbolts : metric series | |

|---|---|

| Nominal diameter | Length |

| mm | |

| M10 | 1.17 |

| M12 | 1.32 |

| (M14) | 1.48 |

| M16 | 1.48 |

| M20 | 1.80 |

| M22 | 1.80 |

| M24 | 2.09 |

| M27 | 2.09 |

| M30 | 2.09 |

| M33 | 2.09 |

| M36 | 2.09 |

| M39 | 2.09 |

| M42 | 2.09 |

| M45 | 2.70 |

| M48 | 2.70 |

| M52 | 2.70 |

| M56 | 2.70 |

| M64 | 2.70 |

| M70 | 2.70 |

| M72 | 2.70 |

| M76 | 2.70 |

| M82 | 2.70 |

| M90 | 2.70 |

| M95 | 2.70 |

| M100 | 2.70 |

Nominal length

The tolerances of nominal length shall be as given in table 6.

The

preferred nominal lengths are given in table 7. If lengths other than these are requested (see appendix C)

the

increments of length should be as given in table 9.

NOTE 2. Length of point is included in nominal length (see 1.2.2.1).

| Increments of nominal length of studbolts: metric series | ||

|---|---|---|

| Nominal Length | Increment | |

| Over | Upto and including | |

| mm | mm | mm |

| -- | 65 | 5 |

| 65 | 200 | 10 |

| 200 | 300 | 20 |

| 300 | -- | 25 |

Length of thread

For studbolts having plain portions as shown in figures 1(b), 1(c) and 1(d), the basic length of thread

shall

be the nominal diameter plus 10 mm.

For studbolts as in figures 1(b) and 1(c) , the tolerances on the length of thread shall be plus 2 pitches,

minus 0.

Length of reduced diameter portion

The basic length of the reduced diameter portion shall be 0.6 times the nominal diameter (see figure 1(d)

and

item (d)(5) of appendix C.

The following tolerances shall apply to this dimension:

(a) + 0.75, -0 mm for lengths up to and including 28 mm;

(b) + 1.50, -0 mm for lengths over 28 mm.

Length of thread plus length of reduced diameter portion

The following tolerances shall apply to this dimension:

(a) ± 1.0 mm for nominal diameters up to and including M48;

(b) ± 2.00 mm for nominal diameters over M48 and up to and including M100.

Ends

The ends of studbolts shall be finished with a point having an included angle of approximately 90 degree to a depth slightly exceeding the depth of thread. Nominal lengths of points for reference purposes shall be as given in table 8.

Diameter of plain portion

The diameter of the plain portion shall not exceed the maximum values given in table 5.

NOTE. The diameter of the reduced portion should be stated by the purchaser in the order (see appendix C).

Under

normal conditions a minimum of 0.95 times the minor thread diameter is used, but for studs subject to

particularly onerous conditions (such as high temperature service) diameters less than this may be used.

Screw threads

Screw threads for studbolts for all materials other than mild or carbon steel shall comply with the requirements given in table 10.

| Pitch of screw threads for studbolts:metric series | |

|---|---|

| Nominal Length | Pitch |

| ≤ M27 | ISO metric coarse (see BS 3643) |

| ≥ M30 ≤ M43 | 3 mm |

| ≥ M45 ≤ M100 | 4 mm |

The ISO metric coarse pitch series shall be used throughout the range of sizes for mild or carbon steel.

NOTE. The tolerance class should be stated by the purchaser in the

order (see appendix C), but for most conditions the following are applicable:

(a) class 6g for carbon steel and grades MB7, ML7, MB7A, MB16, MB16A, MB16B;

(b) class de for other materials.